In response to growing demand for precision, robustness and reliability in automation, HIWIN is introducing a new generation of linear guides designed to meet the requirements of integrators and equipment manufacturers. This development marks a significant advance in industrial linear motion, with enhanced performance and optimised service life.

The mechanics of motion are evolving rapidly. In industrial automation, the robotics, machine tool, automated handling and high-precision manufacturing sectors are imposing ever stricter requirements. Linear guides must no longer simply guarantee smooth movement: they must withstand heavy loads, operate over long strokes, offer lasting micrometric precision and maintain a high level of operational availability.

For industrial companies, insufficiently efficient guidance can lead to costly machine downtime, quality degradation or mechanical limitations that slow down production rates. Increasing productivity requirements therefore place the reliability and endurance of guidance systems on a par with their dynamic capacity.

In this context, the choice of a linear guide is no longer a simple design element. It is a strategic factor, influencing equipment performance, maintenance costs and the ability to evolve towards faster and more complex systems.

A generation of Hiwin guides designed to last

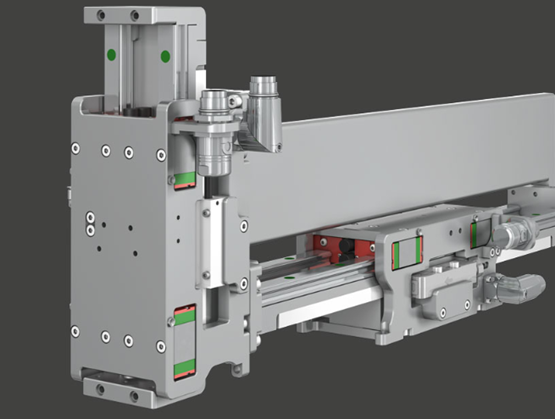

crucial for extended production lines, industrial gantries and large specialised machines. One of the key strengths is the ability to integrate advanced lubrication accessories, reinforced seals or carriage options suitable for intensive environments.

For integrators, these innovations translate into more stable, durable and easier-to-maintain systems. Long-term reliability becomes an engineering argument as well as a lever for economic competitiveness.

Enhanced performance and impact for industrial applications

The introduction of linear guides with a longer service life brings tangible benefits in production environments. Reduced maintenance interventions limit unplanned downtime, improving machine availability. In sectors where every minute of downtime can represent a significant cost, the gain is immediate.

The higher load capacity allows for more robust mechanisms, for example for the Z-axes of machining centres, handling gantries or high-speed palletising robots. The increased rigidity also helps to maintain consistent accuracy, even under load, throughout the entire stroke.

A typical example is large-format cutting or printing gantries, where a stroke of up to several metres must remain stable despite successive accelerations and decelerations. Improvements to the internal geometry of HIWIN guides ensure greater uniformity of movement, limiting vibrations and inaccuracies. For composite machining or laser cutting equipment, this translates into more consistent finish quality and reduced scrap.

Intralogistics automation also benefits from this increase in performance. In a distribution centre equipped with fast shuttles travelling long distances, smooth movement and wear resistance are essential for continuity of service. The new generation of linear guides allows longer axes to be installed without compromising stability or service life.

Implementation, integration and benefits for industrial machine manufacturers

For integrators and industrial machine manufacturers, the benefits of this new generation go beyond mechanical performance alone. HIWIN offers detailed technical resources, including online configurators that allow users to select the appropriate rail, carriage, length, seal options and lubrication devices.

This standardisation improves the fluidity of engineering projects and reduces the risk of errors in the design phase.

Immediate access to CAD files and technical data facilitates collaborative work between design offices, subcontractors and end customers. Less uncertainty also means faster production lead times.

Industrial machine manufacturers benefit further from reduced failure rates and simplified maintenance. In highly competitive markets such as robotics, machine tools and industrial packaging, offering equipment with more robust linear axes is becoming a key differentiator.

While this new generation of linear guides offers significant advances, certain challenges remain to be considered. Integrators must ensure that the entire kinematic chain is correctly dimensioned, as high-performance guidance will only reach its full potential if the motors, mechanical structures and controllers are calibrated accordingly.

Environmental conditions must also be anticipated. Dusty, humid or splash-prone environments require suitable seals, appropriate lubrication and, in some cases, additional protective devices. HIWIN offers a range of options, but their selection must be aligned with the actual context of use.

Finally, sourcing can become a critical parameter for international projects. Premium versions, which are sometimes very specific, must be integrated early in supply chain planning to avoid commissioning delays. For manufacturers operating across multiple sites or markets, this anticipation is essential to business continuity.